Small Current Cell Testing

More

True Wireless Stereo (TWS) Testing | Coin Cell Testing | Material Research

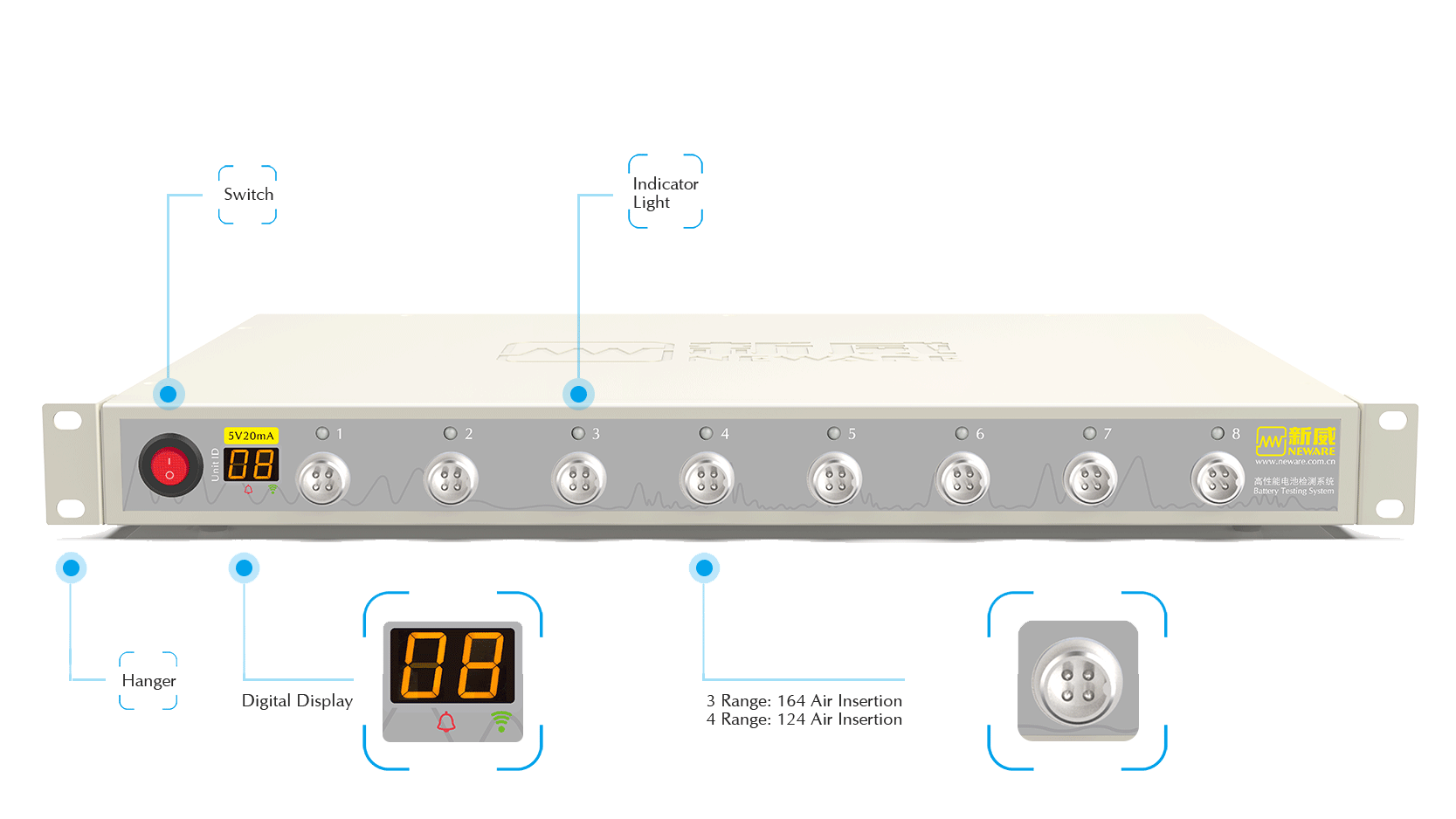

Small Current of 3C Cell TestingCT-4008Q-5V100mA-124

CT-4000 Multi Range mA Battery Testing System, characterized with 0.01% FS accuracy and down to μA capability, enables users to perform DCIR tests, dQ/dV and other basic tests on three-electrode system. It mainly focuses on battery research & development instituions and universities.

Lab

Various kinds of instruments all in need it.

0.01%FS Accuracy, μA Current Unit

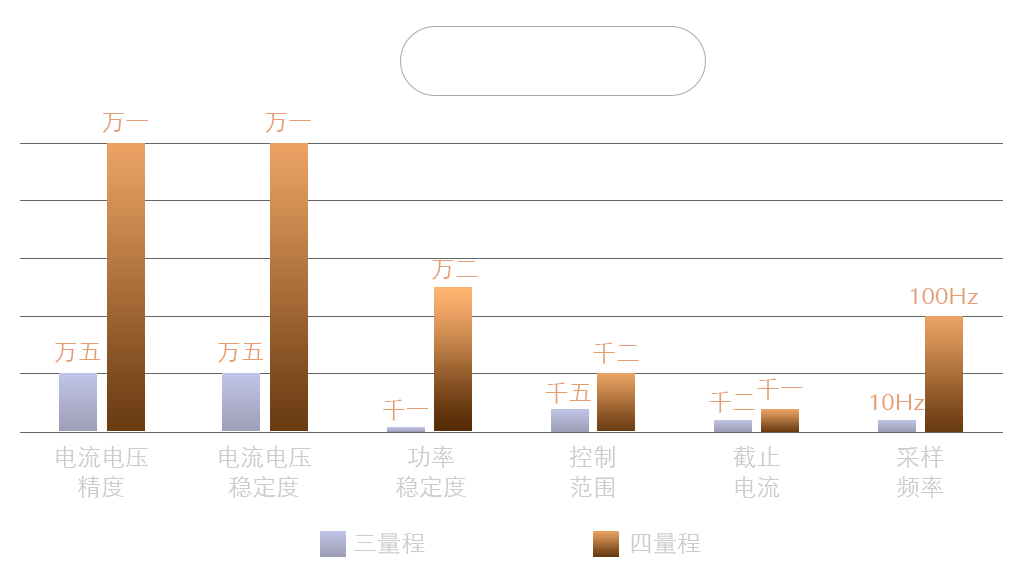

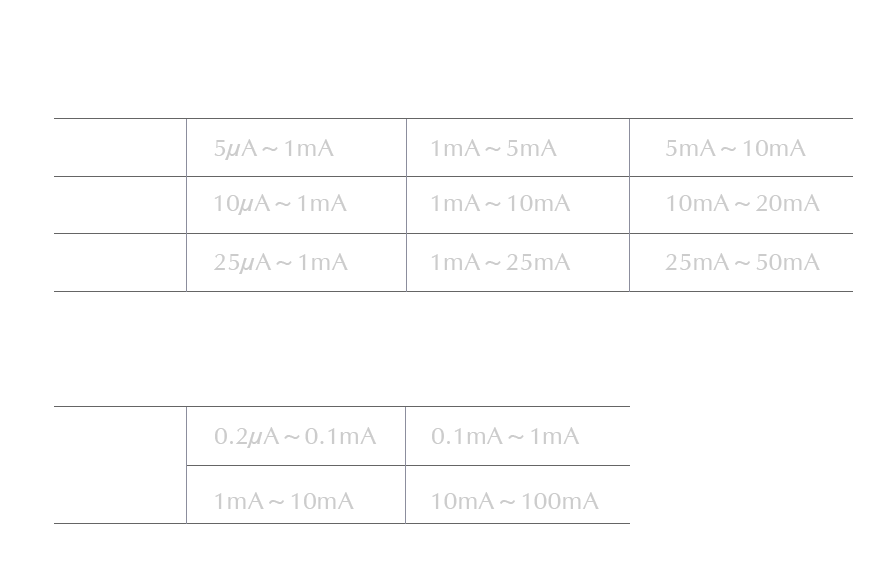

Self transcendence, Reach 4 Range

Self transcendence, Reach 4 Range

-

10Hz/ 100Hz

10Hz/ 100Hz

Data Acquisition Frequency -

500ms

500ms

Min. Pulse Width -

Three-Electrode System

Three-Electrode System

Test -

Charge & Discharge

Charge & Discharge

Rate -

μA

μA

Current Unit -

dQ/dV

dQ/dV

Curve -

DCIR

DCIR -

0.01%FS Accuracy

0.01%FS Accuracy -

4 Range

4 Range -

≤500μs/1ms

≤500μs/1ms

Response Time

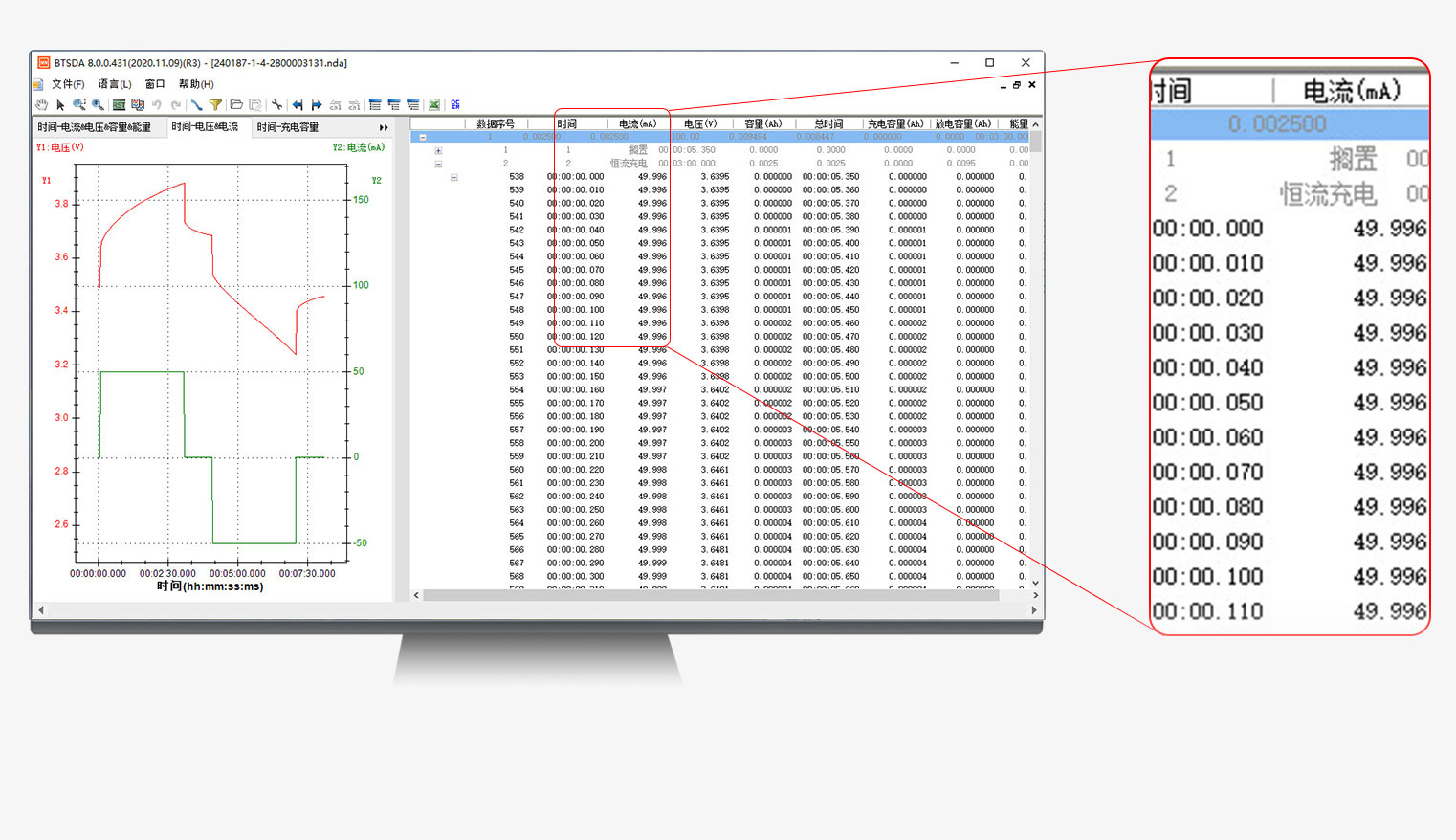

10Hz/ 100Hz Data Acquisition Frequency

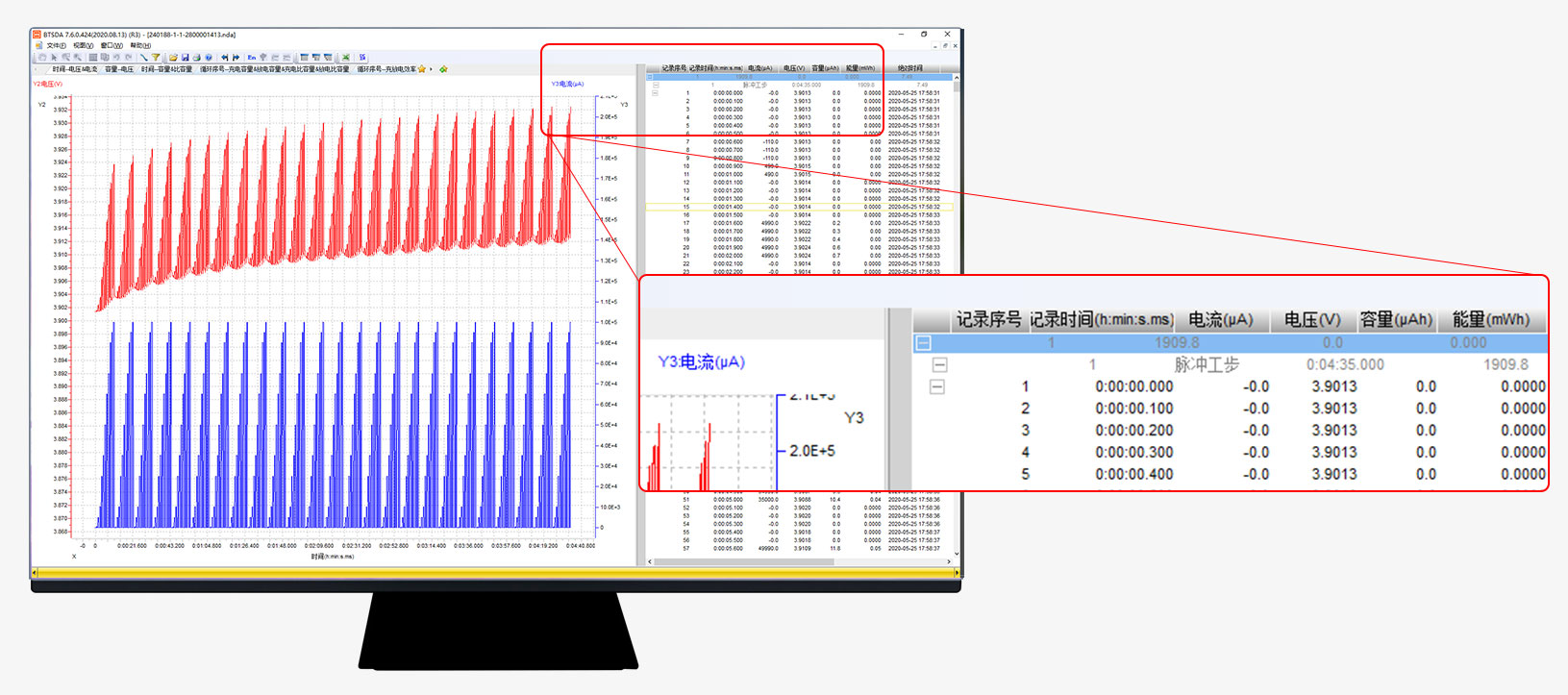

Sampling 10 or 100 data per second in a high speed, recording each voltage and current change accurately.

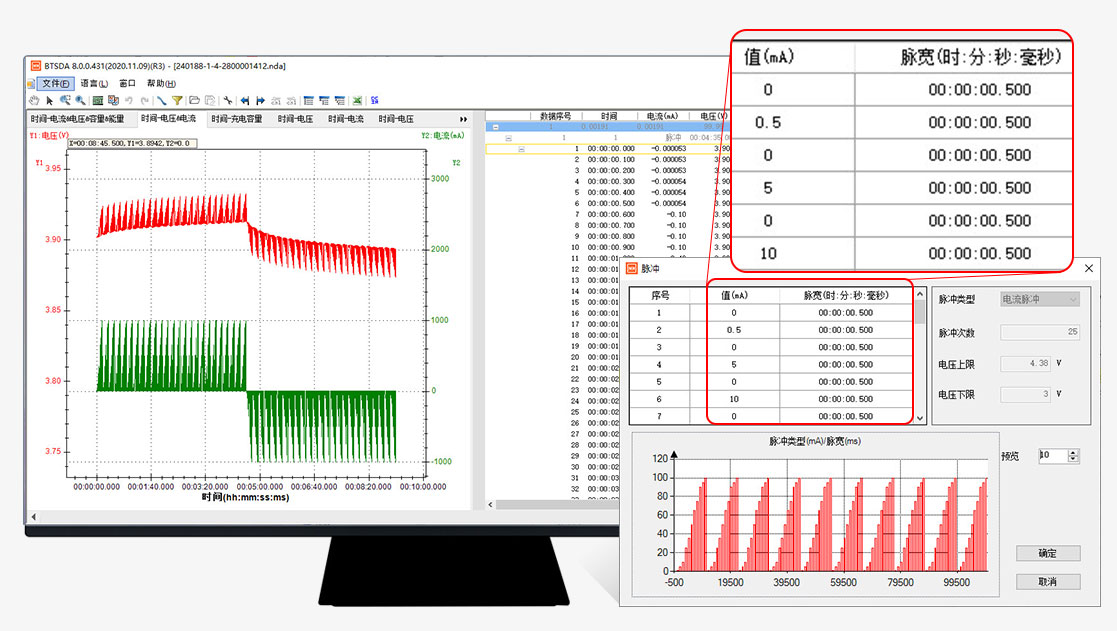

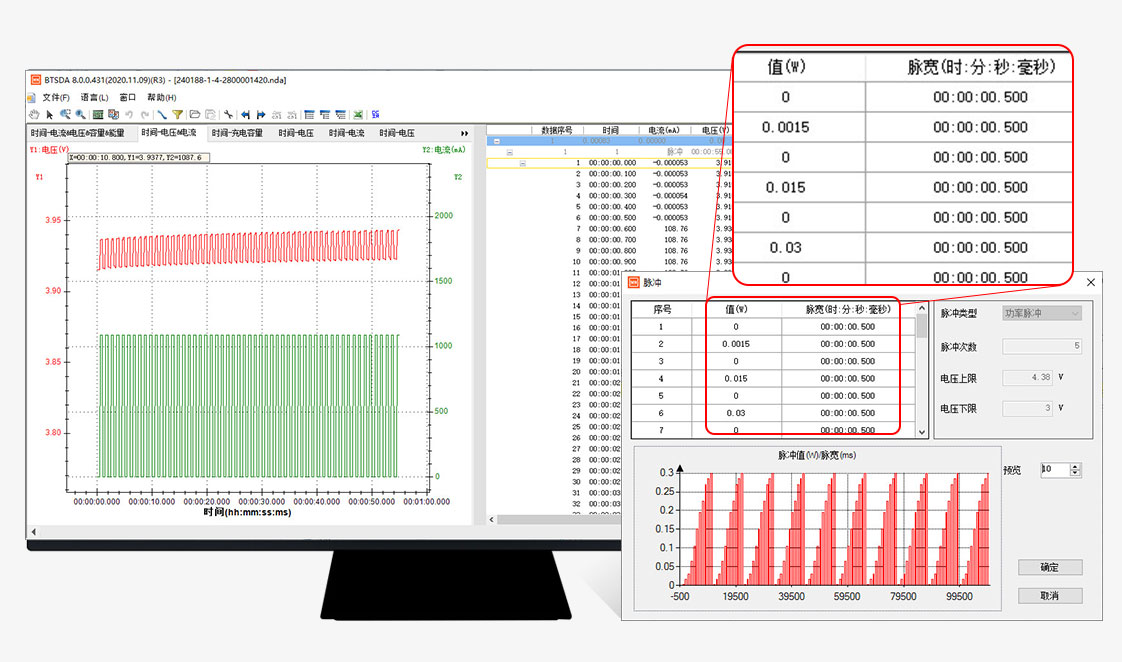

Pulse Width: 500ms

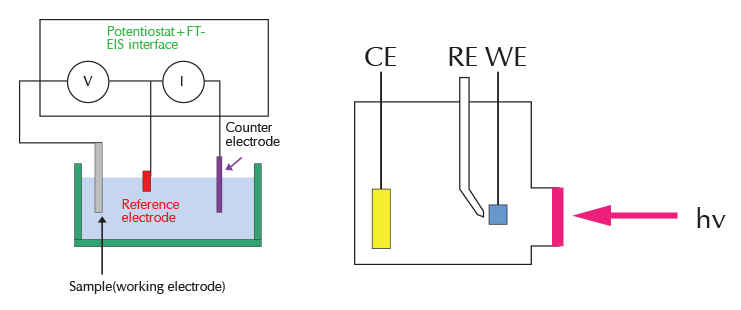

Talk about the concept of the three-Electrode System.

In the field of electrochemical research and battery testing, researchers (students) pay more attention to the potential difference between the working electrode (or auxiliary electrode) and the reference electrode while paying attention to the pressure difference between the working electrode and the auxiliary electrode. The auxiliary channel binding method is adopted to isolate from the main channel without interference, and the data is transmitted synchronously (sampling interval), so as to ensure the accuracy and consistency in the battery tests.

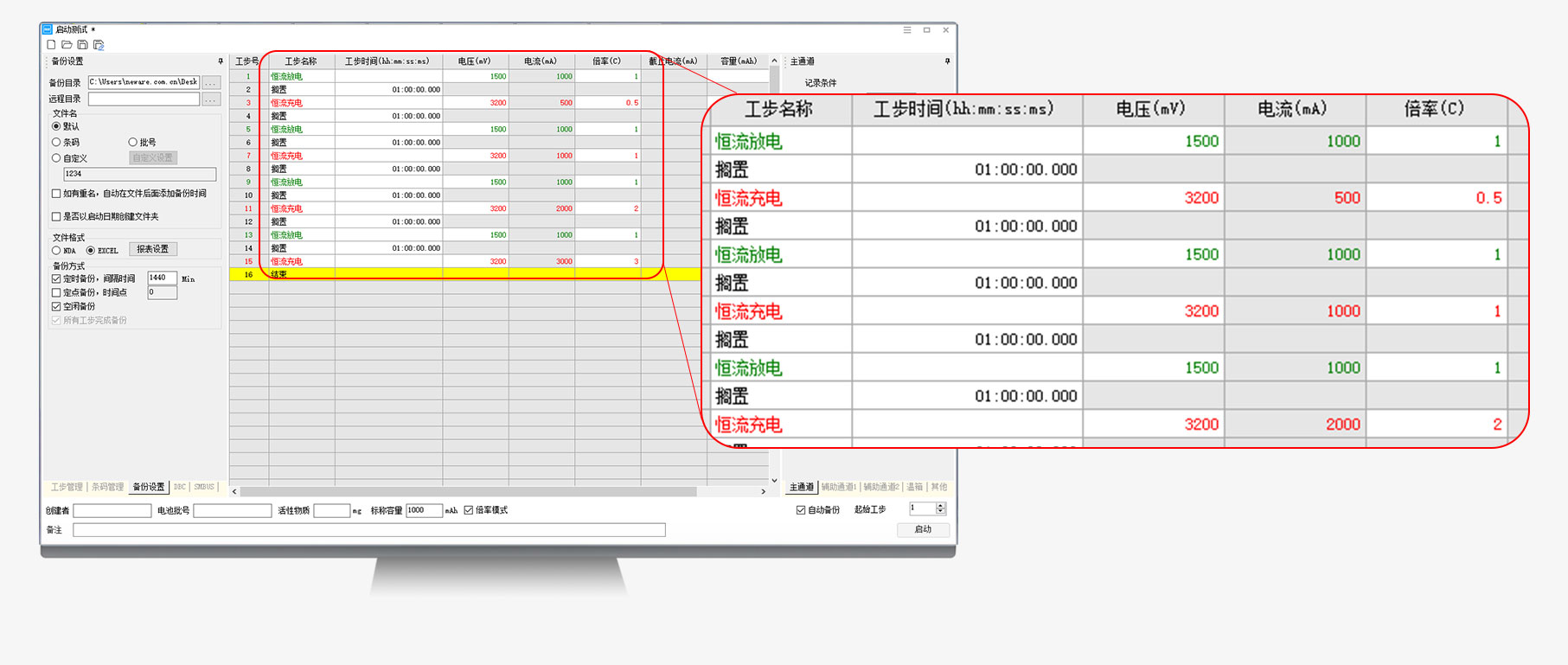

Via different current discharging, we can get the rate performance.

Testing with the μA current unit is more accurate and more convenient.

The design of the μA current unit plays a vital role in the field of current accurate measurement, which is more convenient and more accurate. Generally, magnetoelectric galvanometer can achieve μA level, electromagnetic galvanometer can achieve mA level. Sensitive galvanometer is used for students to check weak current or tiny voltage in DC circuit in the lab. It is a kind of high sensitive magnetoelectric instrument, which can measure the tiny current.

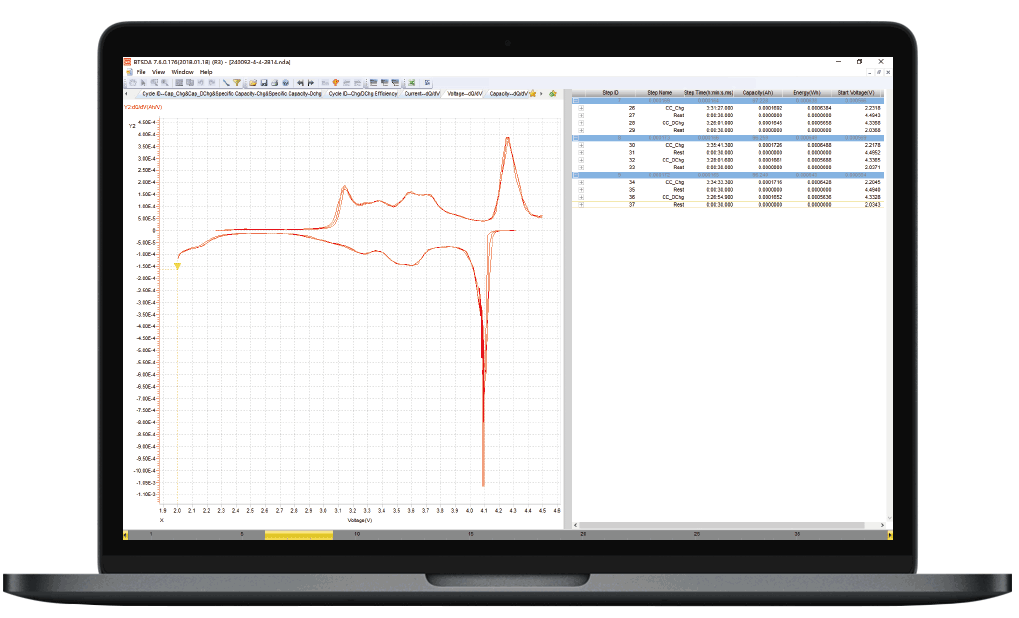

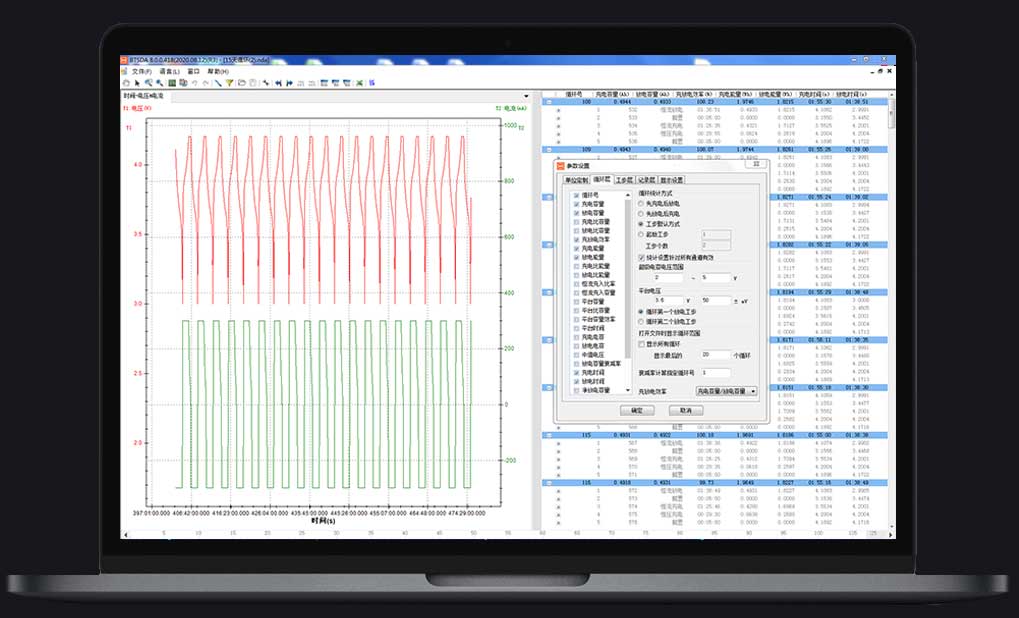

Big news! The latest version of Neware BTSDA is realeased with dQdV function.

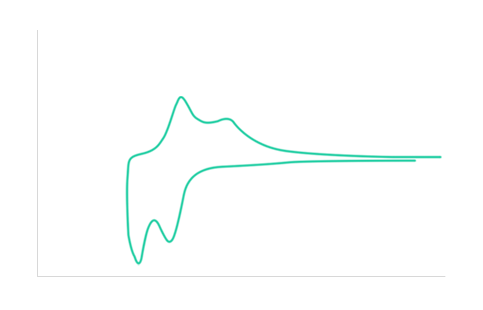

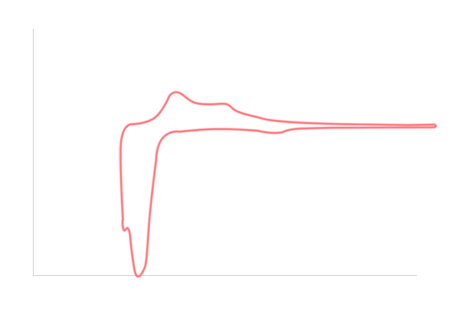

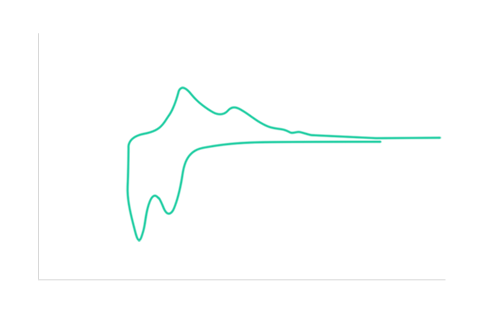

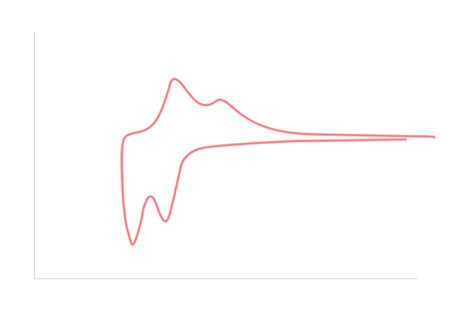

dQ/dV Differential capacity curve: Where there is a peak on the curve meaning the charge and discharge curves have a voltage platform, and different peaks represent different electrochemical reactions.dQm/dV Differential specific capacity curve:dQ/Active material quality/dV.

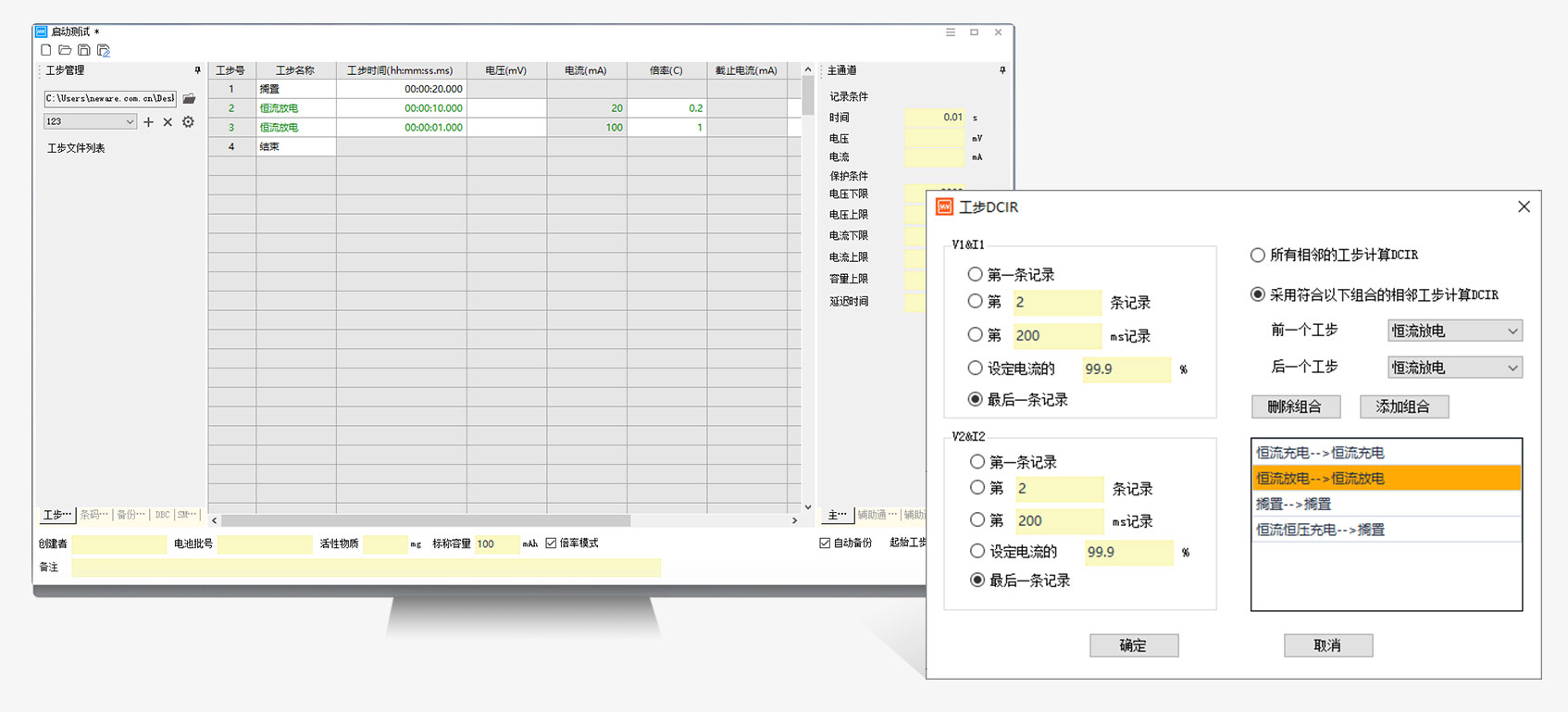

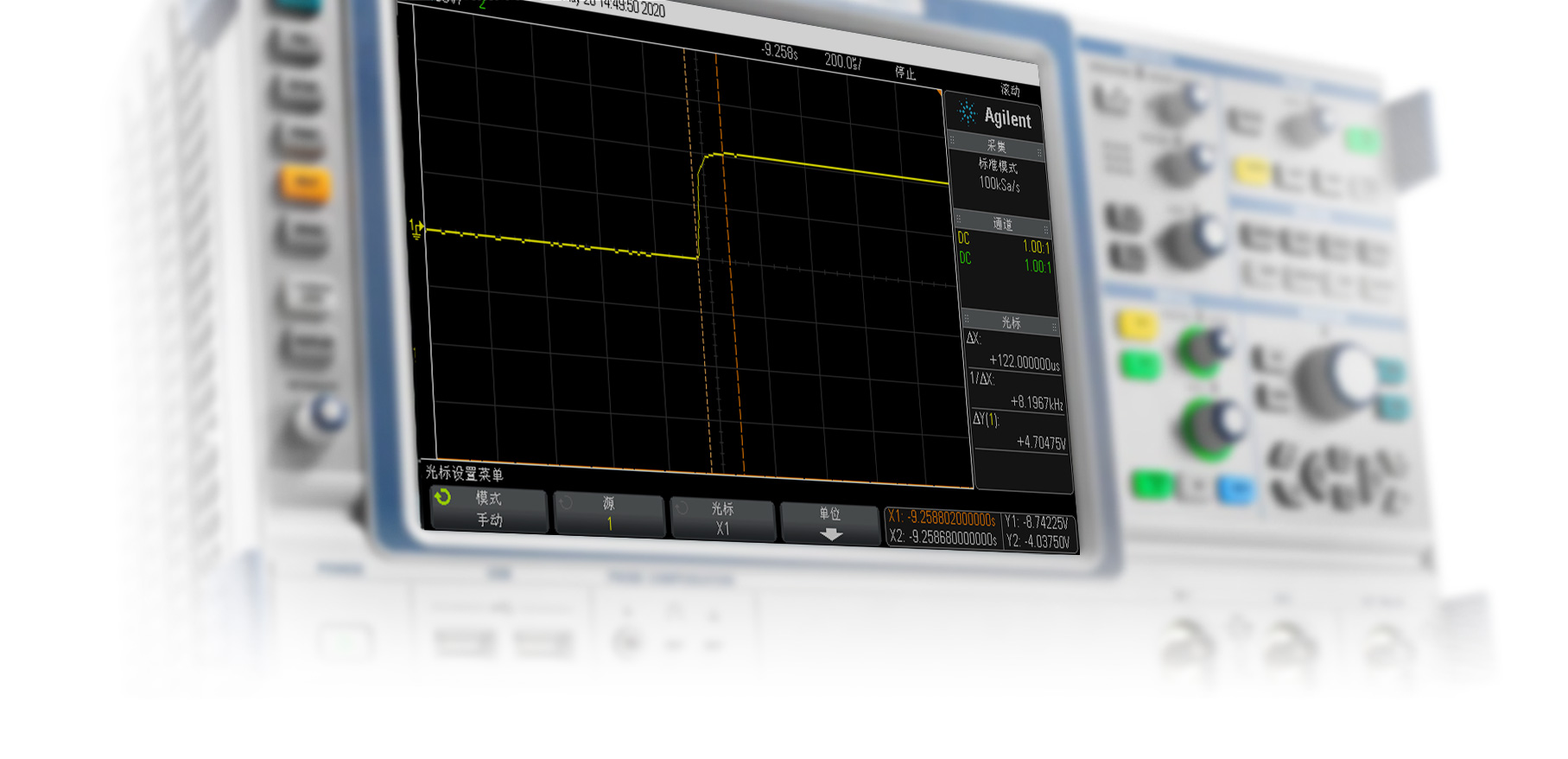

DCIR=▲V/▲I=|V1-V2|/(I2-I1)

Internal resistance, one of the key characteristics of lithium battery, is an important factor affecting the power performance and discharge efficiency of lithium battery. It is also an important specs to measure the power performance and evaluate the life of lithium battery. Test method: Impose a short-time current pulse to the battery and testing the difference between terminal voltage and open circuit voltage. Dividing the difference by the testing current is considered to be the battery DC internal resistance.The software design supports different test methods and different data value taking methods, own strong compatibility, and can be set and calculated according to requirements.

come true 0.01% accuracy

Ultra-lightweight appearance, pro-inspired features, dQ/dV curve,multi-range,0.01% accuracy, and three-electrode system test.

To meet the various requirements adopted in advanced battery research, our equipments can automatically switch the current range in accordance with user settings to maintain consistent accuracy, and can be fitted with additional hardware to provide a number of optional features and capabilities.

Generally, the reaction time is divided into two parts: rise time (rise time ≤ 500 μ s) and fall time (fall time ≤ 500 μ s), and the sum of the two parts shall prevail.

University Program

Joint laboratories help continuously upgrade testing standards.

The Neware University Program is the intersection between Neware technology and the battery technology innovators. Ours advanced battery testing systems witness every step forward of the battery technology.

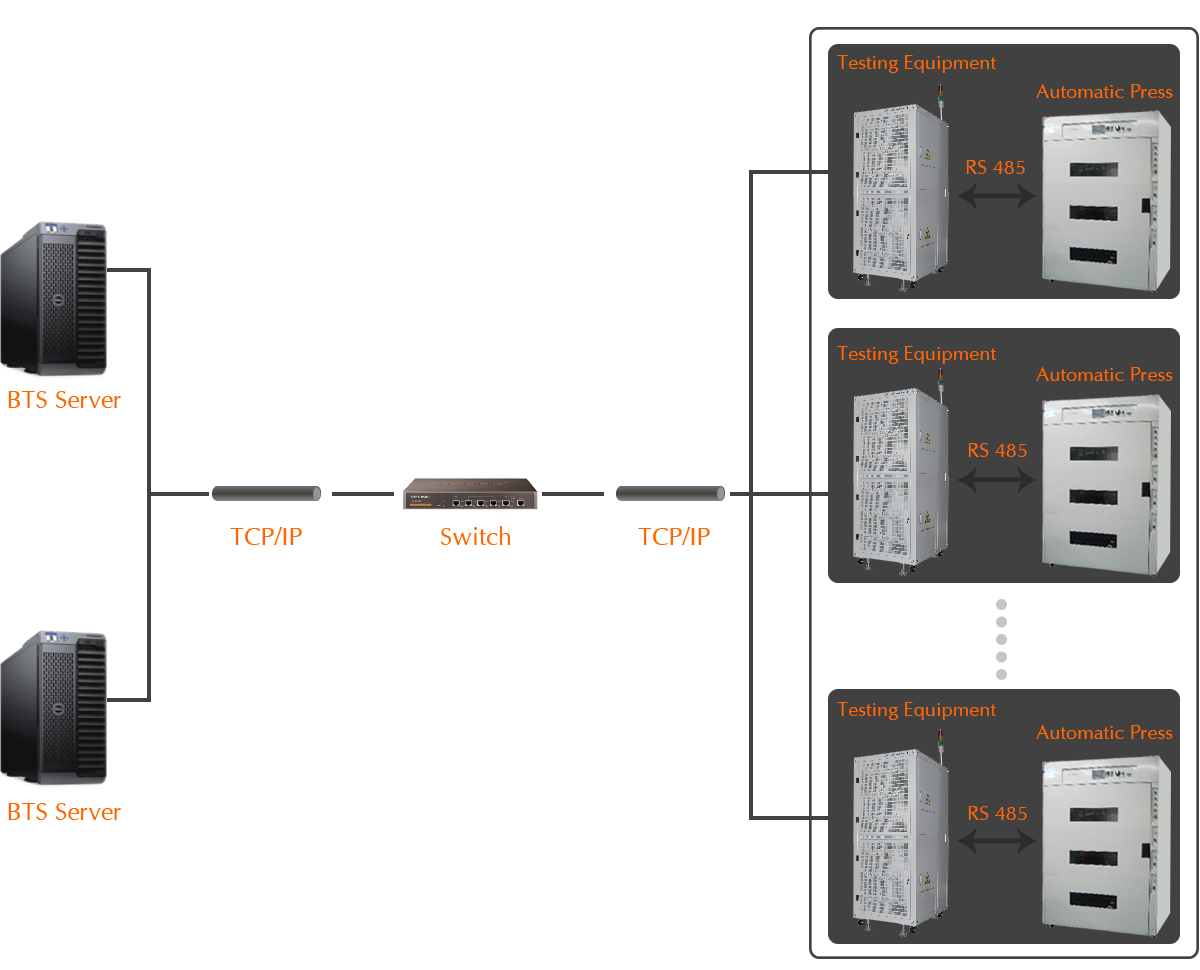

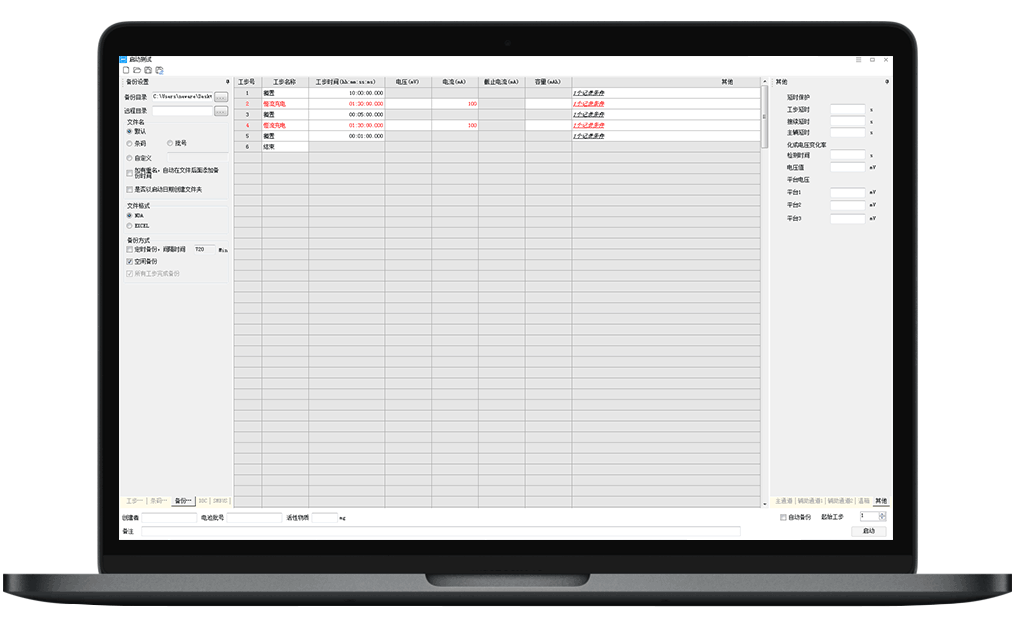

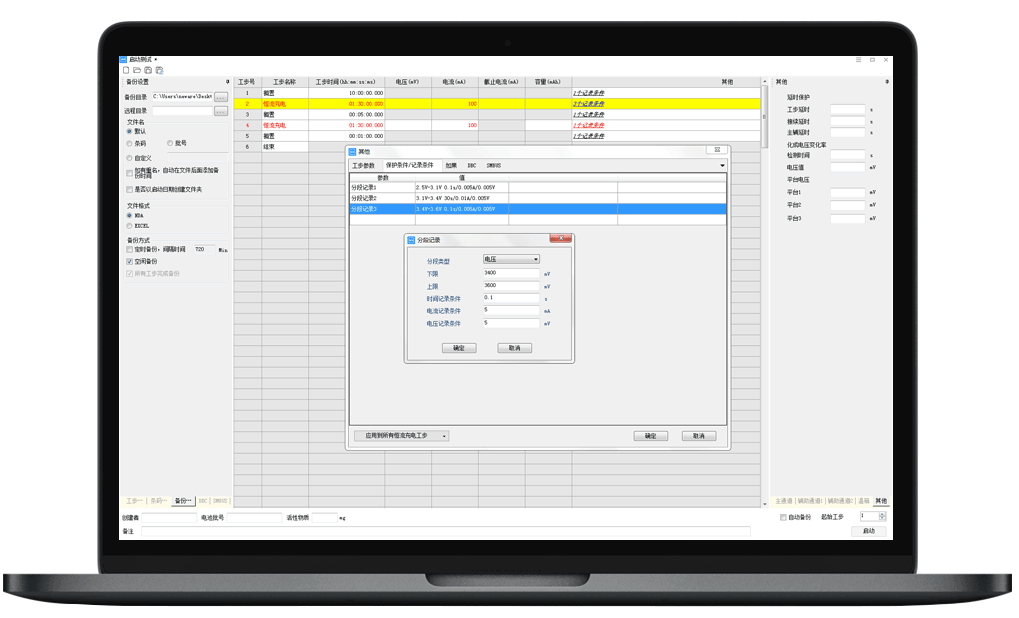

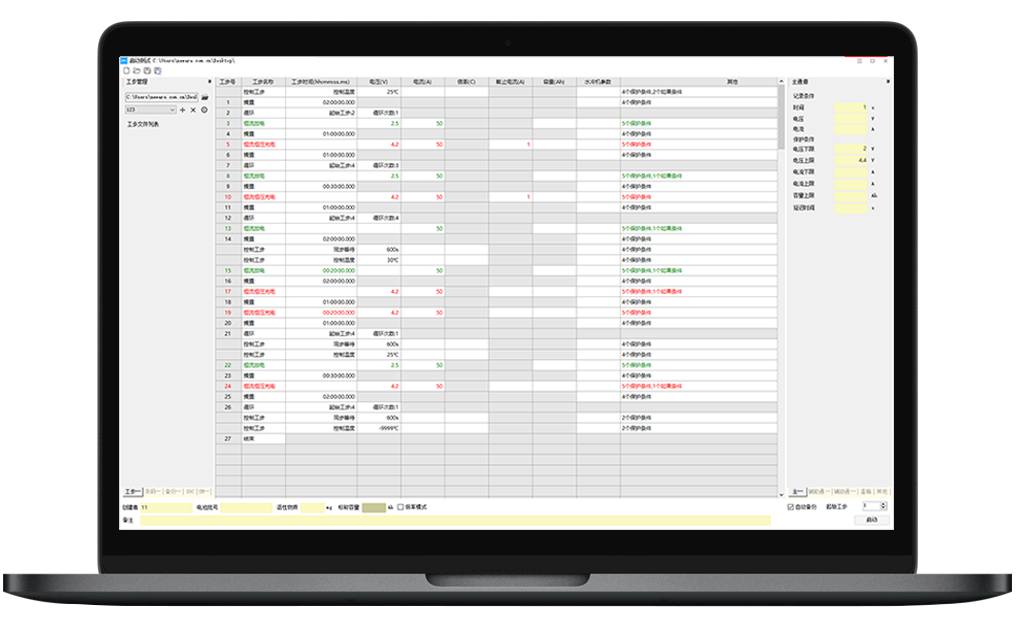

Integrated operation and collaborative work through BTS upper computer control system

NEWARE battery charge and discharge test system realizes integrated operation and collaborative work through BTS upper computer control system, so as to maximize the battery characteristics and functions.

Software

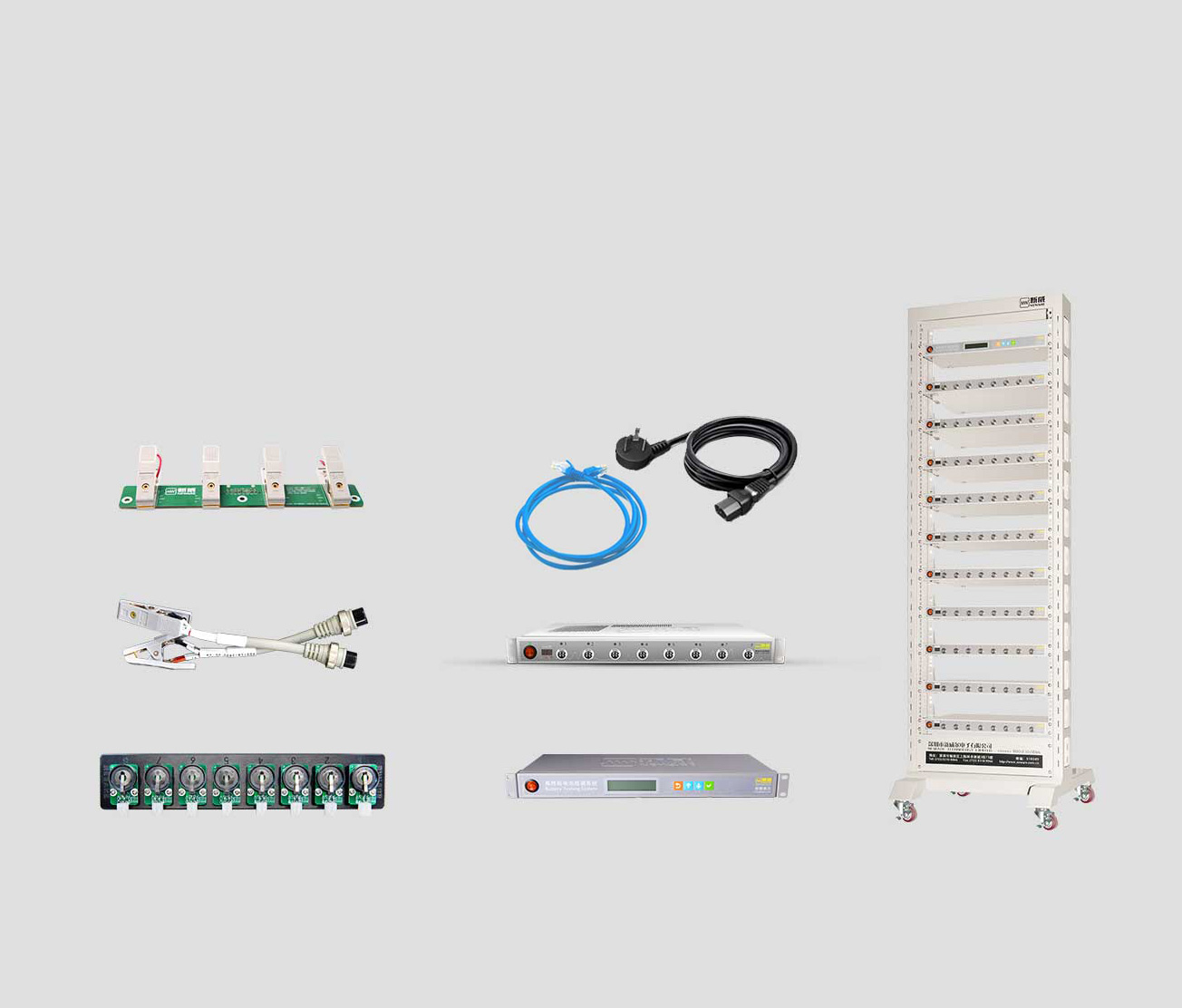

Essential components

dQ/dV

Conditions Switches

Segment-Record Conditions

Control peripheral equipment by communication

Super-capacitor tesing

dQ/dV differential capacity curve: the peak on the curve indicates that there is a voltage plateau on the charge and discharge curve, and different peaks represent different electrochemical reactions.

Battery testing steps need to be estimated for several conditions according to different operations during testing applications; Conditions switches meet requirements for multi-exits programming types. "And" "or" logic operation, "≥", "≤", "=" comparatively calculate; Time duration ”t”, can achieve control requirements for special testing. Every step supports 5 condition switches; Support multi-exits, go to any steps, achieve more flexible process control.

Data record settings for voltage, current and time are supported; 3 segment-record conditions can be set for each step; Every segment can be set: ΔT, ΔV and ΔI .

BTS Server come true the peripheral equipment (Battery tester & Automation) communication control via switch.

The unit of Q is Coulomb, 1 Coulomb = 1A * 1s = 1As; 1Ah = 3600 As(Amp Second); Work voltage U = Charge upper limited voltage - Discharge bottom limited voltage; Working voltage can be set and the EDLC coulomb could be calculated automatically by the software.

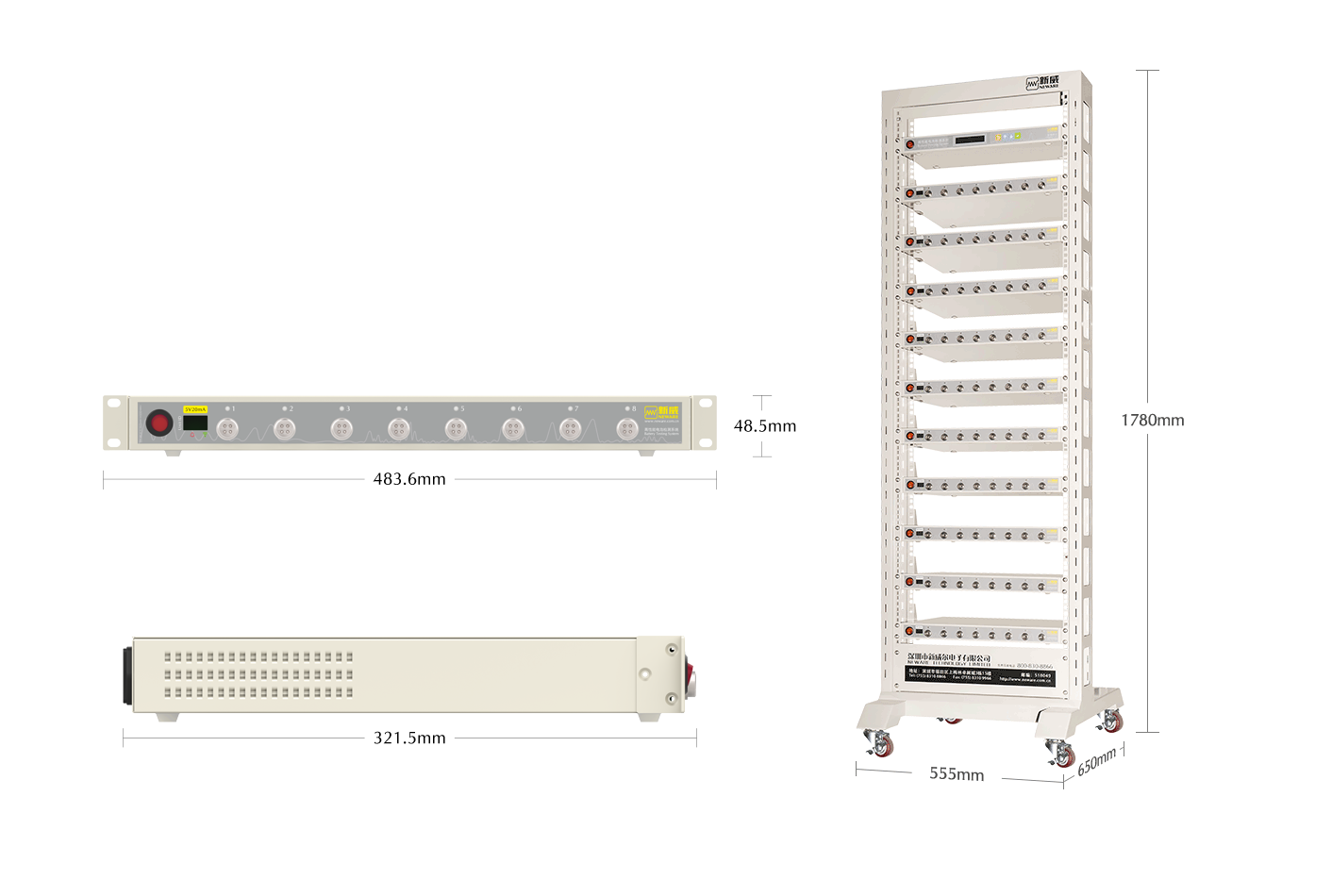

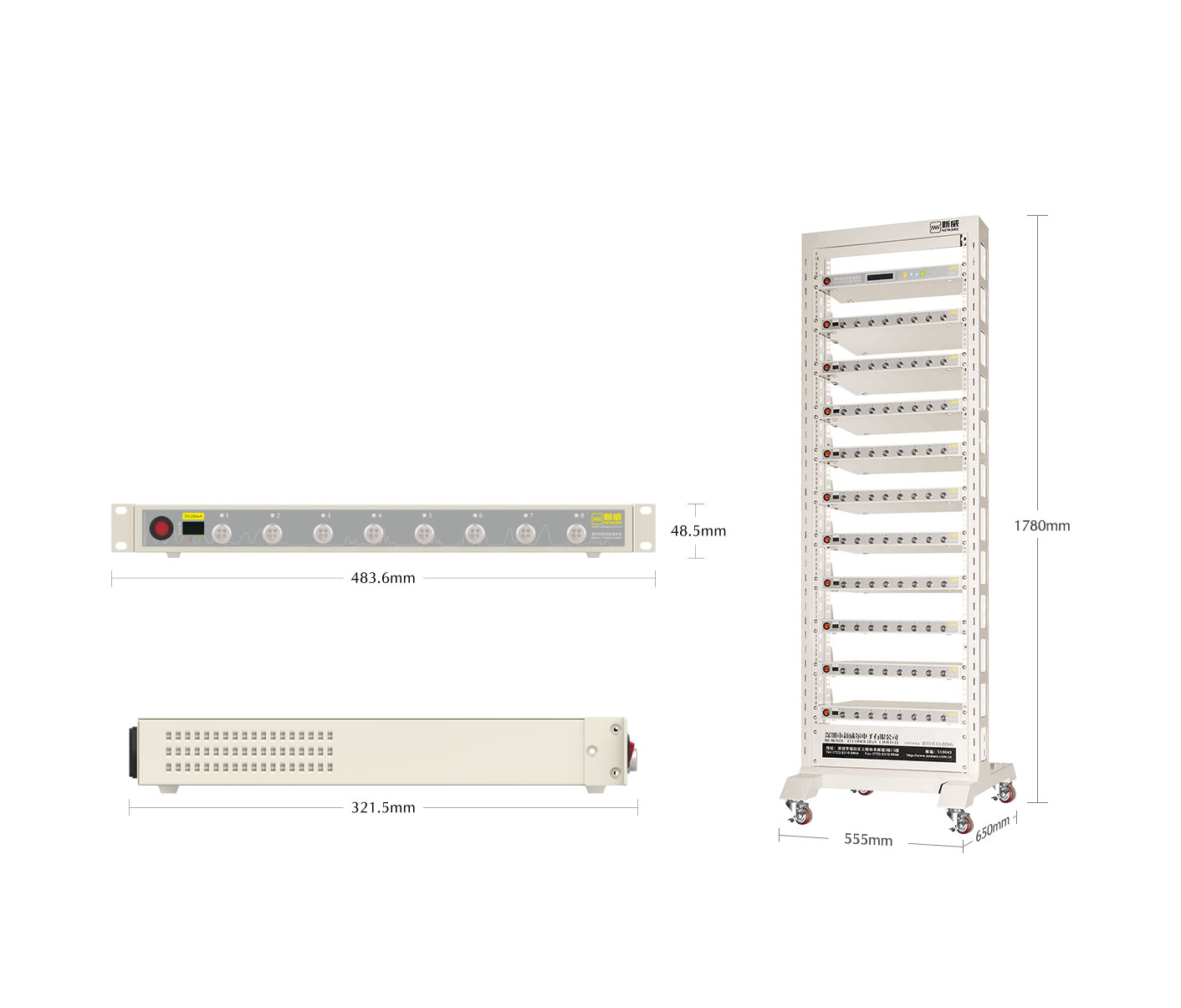

Size and Weight

Net weight of middle machine:2.5kg

Net weight of single equipment: About 5kg

Net weight of single equipment: About 5kg

the Mode of Networking

Accessories

Promoting creativity

Promoting creativity

live:.cid.d7553a84e2f43ba0

live:.cid.d7553a84e2f43ba0

Global - English

Global - English