1. Summary

BATMES (Battery Manufacturing Execution System), the core software platform, services for battery production enterprises. It uses the most advanced information technology to help enterprises control all aspects of the production process, so that it can improve production efficiency, reduce production cost, and build an automatic intelligent digital production workshop.

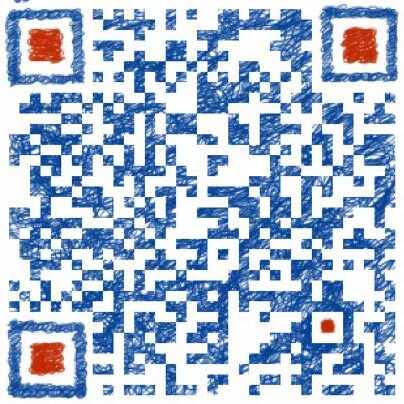

The core working principle of BATMES is shown in the figure above: each production process obtains production factors from BATMES and reports the process result data to BATMES.

live:.cid.e6da7ea6b7fae01e

live:.cid.e6da7ea6b7fae01e

Global - English

Global - English