-

TLM battery testing and managed platform

The battery testing management system was the third mature version, compared to the past two versions, its structure was more reasonable, rigorous and suitable for customers.

-

System Characteristics

According to ISO17025 National Laboratory Accreditation Standards;

Using B/S +jQuery framework, compatible with the IE8+ version, Chrome, Firefox mainstream browser;

Personnel, equipment, resources, application and changeable processes, the multi angle of the electric core data;

Multi hardware device supporting, complex data environment supporting, open interface, multi database type supporting;

High scalability, project reporting, manual data supports twice development flexibly;

The left side is the function of the navigation, the right side is the Tab Sheet operators.

-

Completable Testing Process Management

Coverage the whole testing process from the testing application to the release of the report;

Testing Procedures:

Submit order → Pre-review order → Review order → Collect sample → Scheduling → Start test → Upload testing

Reports →Audit testing reports →Approve testing reports →Release testing reports →handle the samples →end;

The process of the report-collection:

Change the application →Upload the report →Report audit →Approve report →ending;

Different query of the testing report: individuals, departments and all.

-

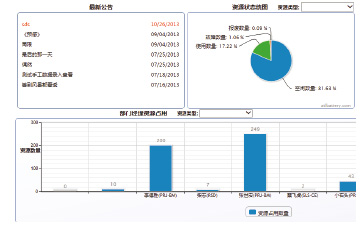

Schedule the Graphic Interface

Personnel task status and test cabinet channel status are clear at a glance;

It is intuitive and simple to operate with graphical mode;

The discharged battery and being testing channels can continue to work;

It can improve work efficiency if the scheduling personnel focus on scheduling.

For laboratories (TLM)

MES

BATMES (Battery Manufacturing Execution System), the core software platform, services for battery production enterprises. It uses the most advanced information technology to help enterprises control all aspects of the production process, so that it can improve production efficiency, reduce production cost, and build an automatic intelligent digital production workshop.

The core working principle of BATMES is shown in the figure above: each production process obtains production factors from BATMES and reports the process result data to BATMES.

BTS Battery Information Management System

The data, that is recorded in the process of battery formation, grading and testing via database, can completely traceability and use through battery bar code, such as battery production and testing data.

NBIS supports a variety of equipment and processes. In addition to tracing the data of formation, grading and testing equipment, NBIS can also realize the acquisition and utilization of the testing data of the third-party equipment when it provides interface or file access. One system can solve the problem of low efficiency of management and query caused by the decentralization of user equipment and system.

Through data cleaning and conversion, NBIS retains the key data in the process of battery production and testing. The typical applications of these data include: data query and automatic report analysis, automatic report generation according to report template, battery sorting and grouping according to conditions.

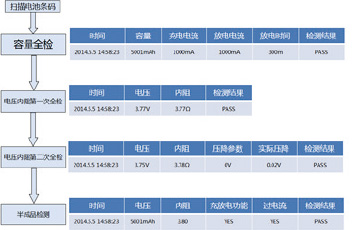

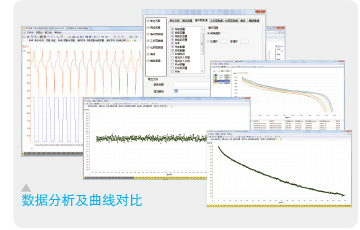

Graphical Display of Test Data

Multiple traceability conditions support;

Through the battery bar code, all the testing data can be traced back;

The system will display all the test data of the battery in a graphical way intuitively and clearly;

It can show the complete traceability chain of battery test data, and can also query the test data of a certain process separately;

The pass rate of the process can be counted and analyzed in order to improve process stability and yield.

Flexible Process Addition

When customers buy new equipment, they don't need to change the program. They can customize the new process and information directly, so they can easily integrate the testing data of new equipment;

NEWARE battery testing traceability system is compatible with a variety of battery testing equipment all over the world, such as MACCOR, ARBIN, HANGKE, JINGSHI, TITAN.

Simple Operation and Friendly Interface

Basically can achieve zero learning cost. You can use it directly just when you open the browser;

Compatible with IE8 +, Firefox, Chrome and other mainstream browsers;

Consistent, unified, beautiful and friendly user interface design;

Interactive reminder via Ajax makes it much more intuitively and quickly. What's more, it also simplify the user operation steps.

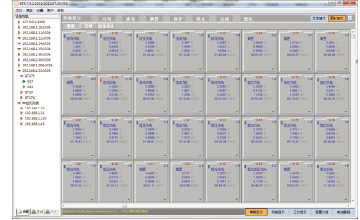

Client

BTS client adopts C/S architecture, realizes network communication control based on TCP/IP, centralizes equipment management and testing data, so that it can realize high-performance testing control.

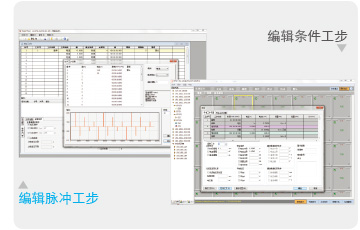

Step Build

The step editor supports two modes: standard step and advanced step. It supports conditional step and single step to set record condition and protection condition.

Data Analyzer Software

BTSDA (Battery Testing System Data Analyzer) is used for data analysis, custom curve drawing and custom report, which also supports curve comparison, battery consistency evaluation and analysis.

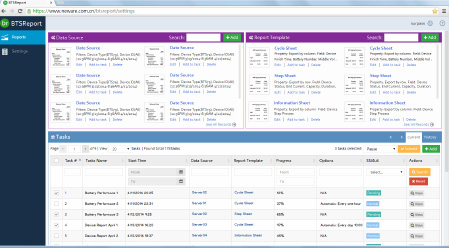

Report

Comprehensive report is a software product based on B/S structure, which mainly aimed at helping NEWARE BTS battery test equipment users come true the testing data statistics, analysis, export and so on.

Users can easily connect to the report server to browse and operate the testing data under their own authority anytime and anywhere when there are networks.

It supports specifying data sources according to equipment number, unit number, channel number, test time range, bar code and other conditions. Exporting data for product development, test result analysis and other purposes;

Supporting the calculation and statistics of testing data for facilitating customer analyze testing data;

Support exporting report management;

It supports flexible definition or adjustment of data export format (definition of data template) according to requirements.

The development of this report is ultimately to replace the customized report development of different customers. It not only solve the limitations of developing customized report system for different BTS customers' needs, but also focus on meeting NEWARE customers' different needs of comprehensive report system functions, which has strong continuity and expansibility.

Barcode

After scanning the battery bar code by barcode scanning software, the bar code can be bound with the test data to realize the management and traceability of historical data.

Basic Operation of Software

/

/

Global - English

Global - English